- Home

- News Release

- Product Releases

- Oki Electric Cable commences sales of "Transparent FPC" combining transparency with high heat resistance

News Release

Oki Electric Cable commences sales of "Transparent FPC" combining transparency with high heat resistance

- Flexibly supporting the diverse wiring requirements in flexible devices, etc. -

Oki Electric Cable Co., Ltd. (President: Masasuke Kishi, Head Office: Kawasaki-shi, Kanagawa-ken, hereafter referred to as Oki Electric Cable) has recently developed the "Transparent FPC" flexible printed circuits (*1), adopting transparent polyimide (*2) film as the base material to offer excellent transparency and heat resistance. This product will commence sales today. This product will be exhibited at the "JPCA Show 2017" (Booth No.5E-04) which will be held at Tokyo Big Sight from Wednesday 7 - Friday 9 June 2017.

FPCs that are lightweight and flexible are widely being used for the internal wiring of devices, where stringent weight and space restrictions apply as they continue to become lighter and more compact. Traditionally, FPCs were mostly used in concealed locations such as inside of an instrument. In recent years, however, more FPCs, including those colored in white or black, are used in more conspicuous locations to meet demands for devices that are superior in design. FPCs are also used in wider varieties of applications including flexible devices such as flexible displays and touch panels, as well as electronic instruments that reflow (*3) semiconductor devices such as LED (*4). Transparency is vital for FPCs that are in these kinds of electronic instruments.

Polyimide film featuring high heat resistance is popularly used as the base material for FPCs but it has insufficient transparency. Polyester (*5) film is a suitable base material for increasing the transparency of FPCs, but it has limited heat resistance and may warp or change in size when heat is applied during reflow soldering.

Oki Electric Cable worked on the development of FPCs that offer transparency while retaining high heat resistance - "Transparent FPC". Oki Electric Cable addressed the challenge of warping/size change due to heat generation during reflow by adopting heat-resistant and transparent polyimide film for the base material and enhancing the transparency and flexibility by using the non-adhesive copper-clad laminate (*6) developed jointly with Asahi Denka Kenkyusho Co.,Ltd. and DKN Research LCC. This product can be used in flexible devices, as well as wearable devices with high design requirements and devices used in the medical and other fields.

Oki Electric Cable will continue to actively develop new products to accommodate the constantly diversifying customer needs.

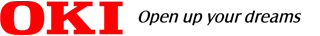

Comparison with conventional products

Left: "Transparent FPC" The background color (outer edge of the board) can be seen through.

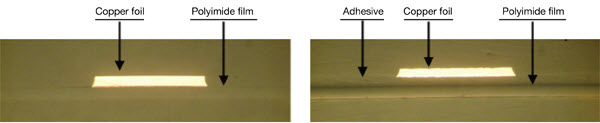

Left: "Cross-section of transparent FPC" Higher transparency and flexibility are achieved by the non-adhesive structure.

Target sales

100+ million yen in fiscal 2017

Overview of Asahi Denka Kenkyusho Co.,Ltd.

Company name: Asahi Denka Kenkyusho Co.,Ltd.

Head office: Tokyo, Narima-ku, Asahi-machi 2-17-7

Founded: 1 July, 1966

Capital stock: 10 million yen

Director: Masanori Mizoguchi, Managing Director

Employees: 25

Business: Plating of wafers and FPCs, ceramic plated circuits, and HDD components,

special surface treatments, technology development

Company URL: http://www.adk-lab.co.jp/index.html

Overview of DKN Research LLC

Company name: DKN Research LLC

Head office: Massachusetts, USA

Founded: 1 July, 2001

Capital stock: 1000 USD

Director: Kenji Numakura, Managing Director

Employees: 9

Business: Design and development of electronics product packages

Company URL: http://www.dknresearch.com/

Glossary of terms

- *1: FPC (flexible printed circuits)

A bendable print circuit board.

- *2:Polyimide Abbreviation: PI

Polyimide has rigid and robust molecular structure and offers the highest levels of thermal, mechanical and chemical properties among polymers.

It is widely used as the insulating substrate for the FPC material and is heat resistant to over 500 deg C. - *3:Reflow

Reflow soldering is a process in which a solder paste is printed on the circuit board and then components are placed on the board before heat is applied to melt the solder.

- *4:LED

Light emitting diode. A semiconductor device that emits light when a forward voltage is applied.

- *5:Polyester (polyethylene terephthalate) Abbreviation: PET

This material is widely used for PET drinking bottles as well as in films and fibers for clothing, etc.

It is heat resistant up to approx. 120 deg C. - *6:Non-adhesive copper-clad laminate

A copper-clad laminate that does not contain any adhesive and consists only of polyimide film and copper foil (A laminate of polyimide film and copper foil glued together is the main material used to manufacture FPCs).

- Press contact:

- Corporate Planning Office

Phone: +81-44-754-4369

Contact Form: https://www.oki.com/cgi-bin/inquiryForm.cgi?p=k001e