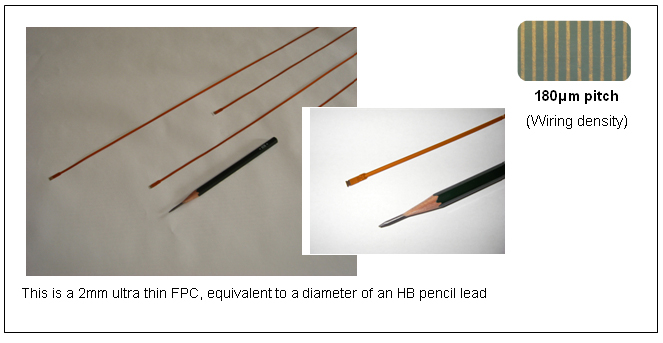

OKI Electric Cable Develops Industry's First 2 mm Width, 3M Long Ultra Thin/ Long FPC

- Achieves over twice the wiring density of thin cables -

KANAGAWA, Japan, June 10, 2009 - OKI Electric Cable (TSE: 5815) today announced that it has developed an ultra thin, ultra long flexible printed circuit (FPC). This newly developed FPC achieves a narrow width of 2mm with a length up to 3m. 2mm-width FPC had been difficult to make even at smaller sized FPC. This is an industry first and sales of this FPC starts today. This ultra thin and ultra long FPC offers a wiring pitch of 180 m, which enables over twice the density of conventional thin cables.

"This new FPC converges OKI Electric Cable's core technologies to make FPCs that are ultra thin, highly flexible, long and that enables high-speed data transferring. This combination enables customers to have flexibility when designing products," said Takashi Hattori, President of OKI Electric Cable. "Because of these characteristics, this FPC expands the applications to microscopes, robots, and to applications for sensors used in medical and industrial equipment."

FPC enables ultra thin wiring with its characteristics of being thin, light, highly flexible and highly dense. Because thin and long FPCs were not available, thin cables had been used as wiring material for places that are narrow and long.

The new FPC solves a problem that conventional thin wire cables had, namely that the thinner the cable, the more complex the harness-making process becomes, and the greater the chances of incorrect wiring. In addition, it can mount components and make wiring lighter, thinner and more flexible, which could not be done with existing thin cables. It will now be easier to make functional and modular devices employing surface mounting of low profile connectors*1 and component packaging such as for LEDs and CCDs (Charged Coupled Device).

10-pin wiring can be complimented with a single 2mm-width FPC without the tangles and kinks that can occur with normal thin cables, and it can be as thin as 50 m thickness. When comparing the flexibility of FPCs to other wiring materials, through an IPC bending test*2, the new FPC was able to achieve a bending spec of over 100 million times (1.5R).

This FPC can be offered with a one or two-sided structure. For the two-sided structure, impedance matching*3 can be done upon customers' requests which will enable the FPC to be used as a thin coaxial cable, such as for transferring image data at high speed.

Leveraging the advantage to offer a solution for cables and FPC, OKI Electric Cable will provide this new FPC to a wide range of areas including industrial equipment and electronic equipment fields.

Glossary

- *1:Low profile connector

This is a short height connector. Some are under 1mm in height and, as devices become thinner, find applications in making connections in narrow spaces.

- *2:IPC bending test

This is a representative flexural bend test for FPC standardized by IPC, the Association of Connecting Electronics Industries.

- *3:Impedance matching

This is to match the electric resistance to optimize signal transmission.

About Oki Electric Cable Co., Ltd.

Established in 1936, Oki Electric Cable Co., Ltd. provides various advanced communications cables, optical cables, and related electronic parts and equipment to the worldwide market. As a member of the OKI Group, Oki Electric Cable Co., Ltd. plays a major role in the group, with the website at http://www.okidensen.co.jp/en/

- Names of companies and products are trademarks or registered trademarks of the respective companies and organizations.

- Press contact:

- Jun Hara

Corporate Planning Office

Phone: +81-44-754-4369

Contact Form: https://www.oki.com/ssl/oec/contact/english_form.html

Reference

Sales plan

- Schedule:

- June 10, 2009

- Sales target:

- 10,000 per month (at volume production)

- Sales price:

- Depends on specification

Characteristics

- Wiring material is highly dense, enabling easy component mounting

- Enables high flexibility (IPC bending test = over 100 million times/ 1.5R)

- Enables impedance matching (for two-sided structure)

- No tangling or kinks

| Category | Specification | Category | Specification |

|---|---|---|---|

| Length(max) | 3m | Surface finishing | Gold/solder plating, etc. |

| Width(min) | 2mm | Flexibility | IPC bending, over 100million times(1.5R) |

| Thickness(min) | 50µm | Solder heat resistance |

260℃,20 seconds |

| Wiring density | 180µm pitch | Operating environment |

-50℃ to 125℃ |

| Structure | One or two-sided | Insulation resistance |

Over 108Ω (DC100V) |