- Home

- News Release

- Product Releases

- JAXA Selects OKI Electric Cable's Long FPC for its Probe to Test World's First Solar Power Sail

News Release

JAXA Selects OKI Electric Cable's Long FPC for its Probe to Test World's First Solar Power Sail

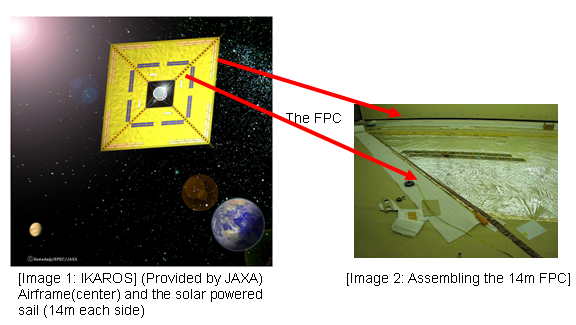

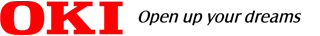

KANAGAWA, Japan, June 2, 2009 - OKI Electric Cable (TSE: 5815) today announced that its 14 meter Flexible Printed Circuit (FPC) was selected by Japan Aerospace Exploration Agency (JAXA), to be used for their probe, "IKAROS*1," which is a small-sized solar-powered sail. Using OKI Electric Cable's 14 meter FPC, JAXA will conduct field tests of solar energy driving power in space, which will be the first time in the world that such power will be put to practical use. OKI Electric Cable will showcase its FPC at the JPCA Show, which will be held in Tokyo from June 3-June 5. (Booth number: 3E-10)

OKI Electric Cable's long FPC is used in IKAROS' sail, which is 14 meters on each side with an area of 200m² . The FPC will serve as the wiring, connecting the thin film solar cells and various sensors on the square film face of IKAROS. During launch, the sail wired by the FPC will be folded in an X-shape and twisted onto a small tube airframe. Once it reaches outer space, the sail will unfold, allowing IKAROS to navigate space with the small solar-powered sail using only photons.

"After several months of performance inspection to check space environmental tolerance, we selected OKI Electric Cable's as our FPC supplier, not just for their reputation for quality but also for their good track record with FPCs," said Tatsuya Endo, researcher of JAXA. "We had been using cable materials for the wiring before, but materials for this small solar power sail must be lighter and smaller as well as be able to survive the extreme space environment. We are pleased to use OKI Electric Cable's FPC for this important mission."

"We are excited to be part of an important field test of solar energy power in space. OKI Electric Cable's FPCs will be perfect for this mission. While it is many meters long with no joints, it is less than one- hundredth the weight and thickness of conventional cables," said Takashi Hattori, President of OKI Electric Cable. "In addition to the relationship we have with our current customers, I believe this new achievement with JAXA will enable us to develop new customers in the fields of medical, industrial and automotive equipment."

OKI Electric Cable's long FPC is made from an OKI Electric Cable-original manufacturing method involving a sheet-line and a roll-line. The two production lines use equipment such as special hole punchers, large exposure machines, a continuous-process heat press, large NC routers, etc. OKI also uses another original manufacturing method called "partial role" production method, and chooses the most suitable equipment from each line. Thus, OKI Electric Cable is able to respond quickly to various customer needs by offering highly reliable and high-quality long FPCs with short turn-around-time.

Glossary

- *1"IKAROS" (Small solar power sail demonstrator):

This will be the first actual solar sail flying an interplanetary voyage. The project code of it is named IKAROS (Interplanetary Kite-craft Accelerated by Radiation Of the Sun), which will demonstrates the membrane deployment and thin film power generation in cruise flight to Venus. - *2Sheet-line: This is an adaptable manned line to manufacture FPCs using sheet-cut materials.

- *3Roll-line: This is an unmanned line to manufacture FPCs using roll materials.

About Oki Electric Cable Co., Ltd.

Established in 1936, Oki Electric Cable Co., Ltd. provides various advanced communications cables, optical cables, and related electronic parts and equipment to the worldwide market. As a member of the OKI Group, Oki Electric Cable Co., Ltd. plays a major role in the group, with the website at http://www.okidensen.co.jp/en/

- Names of companies and products are trademarks or registered trademarks of the respective companies and organizations.

- Corporate Planning Office

Phone: +81-44-754-4369

Contact Form: https://www.oki.com/cgi-bin/inquiryForm.cgi?p=k001e

Reference

Characteristics of OKI Electric Cable's FPC

- Offers FPC in any desired length: Manufacturable in lengths up to 100 m

- Can meet specifications for a wide range of applications:

- Various shield materials can be added

- Components can be easily mounted

- Responsive to requests for environmental features (damp-proof, low emission of gaseous)

- LCP (liquid crystal polymer), PEN (polyethylene naphthalate)

Major specifications

| Category | Specifications | Category | Specifications |

|---|---|---|---|

| Product Width(Max) | 250mm | Layers | 1 - 2 layers |

| Conductor width | 100µm | Bending R | 0.5R(Highly flexible) |