- Home

- News Release

- Product Releases

- Oki Electric Cable commences sales of the "CoaXPress cable" supporting the next-generation CoaXPress interface

News Release

Oki Electric Cable commences sales of the "CoaXPress cable" supporting the next-generation CoaXPress interface

- Offering a wide lineup of models with high-capacity/high-speed transmission capabilities to accommodate diversifying needs and applications -

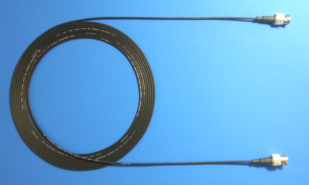

CoaXPress cable

Oki Electric Cable Co., Ltd. (President: Masasuke Kishi, Head Office: Kawasaki-shi, Kanagawa-ken, hereafter referred to as Oki Electric Cable) has recently developed the "CoaXPress cable", which supports the CoaXPress standard (*1) used in machine vision (*2) systems such as image inspection equipment and features high-speed transmission of up to 25 Gbps.

In recent years, the machine vision systems incorporated on image inspection equipment are featuring higher image resolutions in line with the miniaturization of test objects and higher transmission speeds in order to shorten the cycle time (*3). The CoaXPress standard is attracting attention as the new-generation machine vision interface, featuring a high-speed transmission of up to 25Gbps which greatly exceeds the maximum transmission speed of the CameraLink standard (6Gbps) widely being used as a machine vision interface.

In preparation to the future prevalence of the CoaXPress standard, Oki Electric Cable has developed a new machine vision interface cable: the "CoaXPress cable". A complete lineup of models are available to accommodate diversifying user requirements. The "standard type" with superior transmission performance and the "small-diameter" type suitable for wiring in confined spaces, both of which are both available in two versions: The cost-effective "fixed wiring" version and the "movable wiring" version with excellent durability against bending and twisting.

The "standard type" features a long-distance transmission of over 15 meters, making it suitable for use with large devices such as LCD inspection equipment that tend to require long wiring. The "small-diameter type" features a 40% smaller diameter than the "standard type" (in-house comparison), making it suitable for use in small-sized equipment with limited wiring space. Machine vision systems equipped on industrial equipment often feature a mechanism in which the cameras move according to the subject, requiring cables with excellent movement durability. The "movable wiring" version has been developed movement durability to accommodate such requirements.

In future, Oki Electric Cable will continue to actively develop machine vision cables that will accommodate the diversifying customer needs.

Main specifications

| Item | Content | ||||

|---|---|---|---|---|---|

| Applications | Fixing wiring | Movable wiring | |||

| Type | Small-diameter type | Standard type | Small-diameter type | Standard type | |

| Cable | Transmission class | CXP-6 | |||

| Transmission speed | 6.25Gbps/lane, Up to 25Gbps/4 lanes | ||||

| Transmission distance (Standard) | 5m | 15m | 5m | 15m | |

| Connector | Type | BNC or DIN | |||

Features

- Supports transmission speeds of up to 6.25 Gbps/lane.

Supports high-speed transmission speeds of up to 25 Gbps via four line connections. - A lineup of four models is on offer: The standard and small-diameter types featuring different transmission distances are available in "fixed wiring" and "movable wiring" versions to meet different user needs.

- Supports BNC and DIN connectors.

- Movement durability Sliding (*4) More than 3 million times (R=50 mm, "Movable wiring" version only)

Sales plans

Sales start period: May 2016

Target sales: 50+ million yen/year

BNC connector

DIN connector

Glossary of terms

- *1: CoaXPress standard

A digital interface standard. This standard supports high-speed transmission of up to 6.25Gbps in a single cable (and up to 25Gbps with simultaneous connection of four cables) and also supports long-distance transmission of longer than 100 m that is considered difficult with other digital interfaces. The standard is expected to be the next-generation interface for machine vision systems.

- *2: Machine vision

Machine vision systems are used in devices such as component mounting equipment and product label printers to check the product appearance and printing defects using one or more cameras, light source, image capture device, image processing equipment, etc.

- *3:Cycle time

Time or interval required to manufacture a product.

- *4:Sliding

Repetitive reciprocating movement of the cable while bending it in a U-shape and sliding it linearly.

- Press contact:

- Corporate Planning Office

Phone: +81-44-754-4369

Contact Form: https://www.oki.com/cgi-bin/inquiryForm.cgi?p=k001e